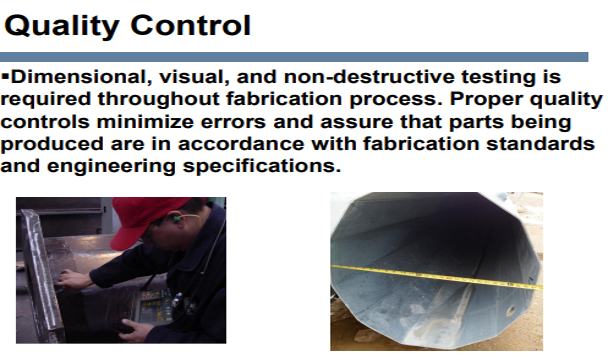

Plant Audit, Inspections (QA/QC), ITP

- Transmission Materials: Steel Pole, Lattice Towers, and Substation Support Structures, Insulator, Conductor, OPGW , Guy Wires Shield Wires and Hardware Assembly

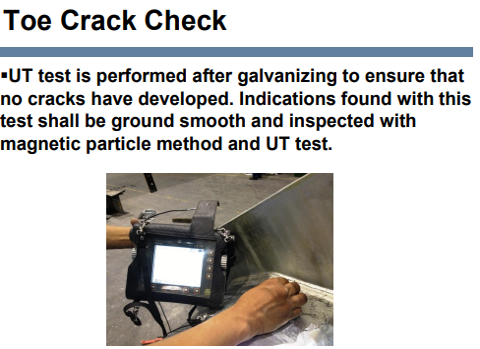

- Weld Inspections – NDT Technique

- Fabrication Shop Audits and on-site Inspections

- Material Sampling (Metallurgical and Mechanical Testing)

- Failure/Root Cause Analysis

- Field Inspection for aging transmission structures

Testing

- Transmission Line Engineering and Manufacturing of Steel Structures (Sustainability Approach)

- Structural Analysis, Design and Detailing of Steel Poles and Lattice Tower

- Full Scale Structural Testing (Witnessing and Validation)

- Electrical Testing: Corona/RIV and others

- Type Testing: Conductor/OPGW/Hardware

- Prototype and Proof of Fit Testing

- Technical Specifications Review

Source Inspections at manufacturing facilities

Determine compatibility of existing and proposed transmission line

- Ensure that the customer receives quality product

- Minimize liability for product failures and construction delays

- Minimize liability for product failures and construction delays

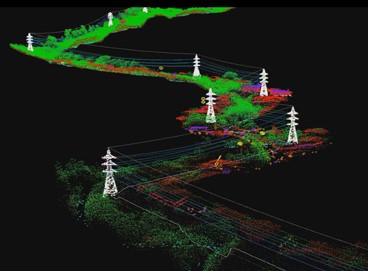

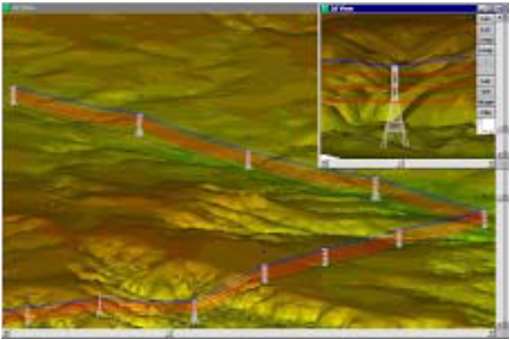

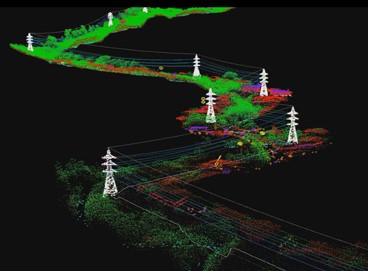

Field Inspections Using Drones

Structure Optimization:

- LiDAR Technology

- High quality information

- Diagnose problem quickly

- No outage required and cost savings

- Safe and healthy work environment

Quality Management System

- SANPEC employs a robust quality management system guided by our principles—customer focus, employee involvement, a process-oriented approach, integrated systems, strategic planning, continual improvement, fact-based decision-making, and effective communication. In building transmission and distribution infrastructure, SANPEC rigorously applies highest quality standards across every stage—from R&D and design to manufacturing, operations, supply chain management, and material sourcing—ensuring that each component and process meets the highest levels of reliability and performance. This steadfast commitment not only exceeds customer expectations but also cultivates an environment where every employee is empowered to drive ongoing quality enhancements.

Innovation Management

- Aligned with the ISO 56000 series—specifically ISO 56001:2024—SANPEC systematically manages innovation through a structured approach that drives sustainable growth and secures a competitive edge by continuously exploring and implementing cutting-edge solutions in transmission and distribution. By fostering innovation in its R&D, design, and operational processes, SANPEC maximizes value creation by unlocking increased value from new products, services, processes, and methods, thereby delivering tangible benefits for both the organization and its stakeholders. This approach not only boosts immediate performance but also steadily builds long-term innovation capabilities, even amid uncertainty.

Change Management

- leveraging in house souftware and tools, SANPEC adeptly manages organizational change to ensure smooth transitions and enhanced adaptability during strategic shifts across all its functions—from R&D and design to manufacturing, operations, supply chain management, and material sourcing. By adopting changes faster, more completely, and proficiently, SANPEC remains fully engaged during disruptive periods, understanding the rationale behind each change. This comprehensive approach, which provides the necessary time, tools, and support for everyone involved, minimizes the risks and costs associated with mismanaged change while maximizing returns on project investments through the effective application of change management principles before, during, and after each project.