Tower Testing And Inspections

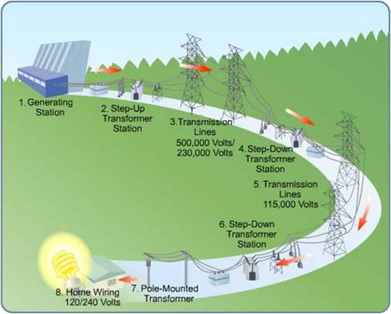

From 69 kV up to 500 kV, we design, engineer, and inspect a full range of overhead transmission line support structures to precisely suit the growing needs of our utility customers. In addition, we provide custom solutions for complex base plates, cross arms, and pole accessories.

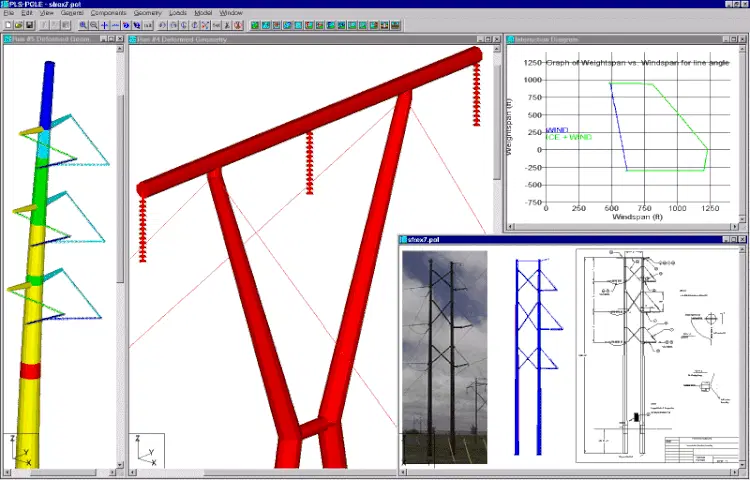

We utilize state-of-the-art design and detailing software to optimize transmission line structures (single circuit, double circuit, H-frames, substation, custom structures) and identify stress concentrations in critical areas through finite element analysis.

- Transmission Line Engineering (Sustainability Approach)

- Full Scale Structural Testing (Witnessing and Validation)

- Minimize adverse environmental impacts

- Optimize the ROW

- Plan resiliency in transmission line system

- Deliver electricity in safe, reliable and an efficient manner

- Provide economic benefits to shareholders and communities

- Use environmentally preferable structures: Steel Poles/Towers

- Utilize lifecycle economics and use best practice specs

- Optimize operational and maintenance practices

Sustainability through Engineering Excellence

Determine compatibility of existing and proposed transmission line

- Voltage (kV) of Line

- Total Length of Line

- Climatic Conditions

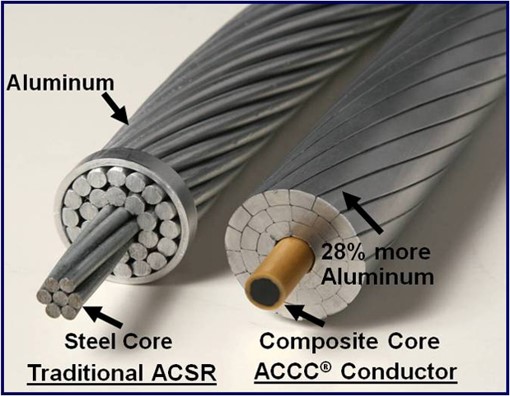

- Type of conductor

- Type of Structures

- Type of foundations

- Design Capacity (MVA)

- Power Delivered (MVA)

- Cost of Conductor ($/ft)

- Cost of Structures ($/lbs)

- Cost of Construction ($/miles)

- Other Misc. Cost ($$ Lump Sum)

T&D Structures

Structure Optimization:

- Type of Material

- Structure configuration

- Optimum and efficient design

- Less waste of material

- Installation cost

- Aesthetic consideration

- Optimum foundation design

- Total life cycle cost

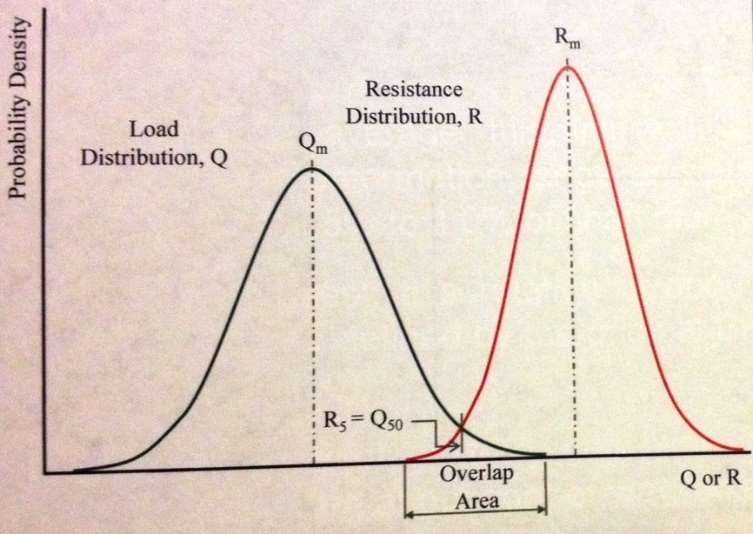

Rubust Transmission Line

Design & Engineering for a robust transmission infrastructure

- Minimize adverse environmental impacts

- Optimize the ROW

- Plan resiliency in transmission line system

- Deliver electricity in safe, reliable and an efficient manner

- Provide economic benefits to shareholders and communities

- Optimize operational and maintenance practices

- Use environmentally preferable structures: Steel Poles/Towers

- Utilize lifecycle economics

- Use best practice specs

T Line Structures Testing

Source Inspections at manufacturing facilities

Determine compatibility of existing and proposed transmission line

- Ensure that the customer receives quality product

- Minimize liability for product failures and construction delays

- Minimize liability for product failures and construction delays

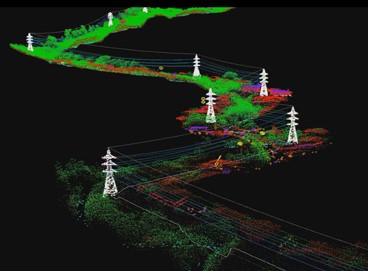

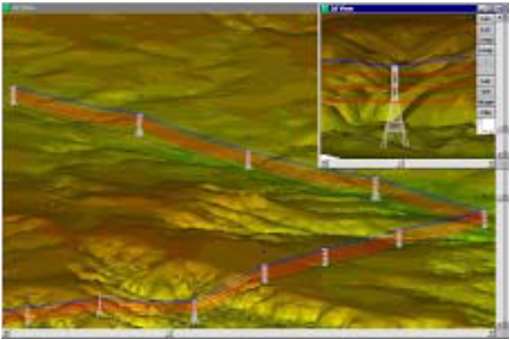

Field Inspections Using Drones

Structure Optimization:

- LiDAR Technology

- High quality information

- Diagnose problem quickly

- No outage required and cost savings

- Safe and healthy work environment

Conductor/OPGW/Hardware

- Inspection of T Line Materials (Steel Poles, Towers, Substation Structures, Insulators, etc.)

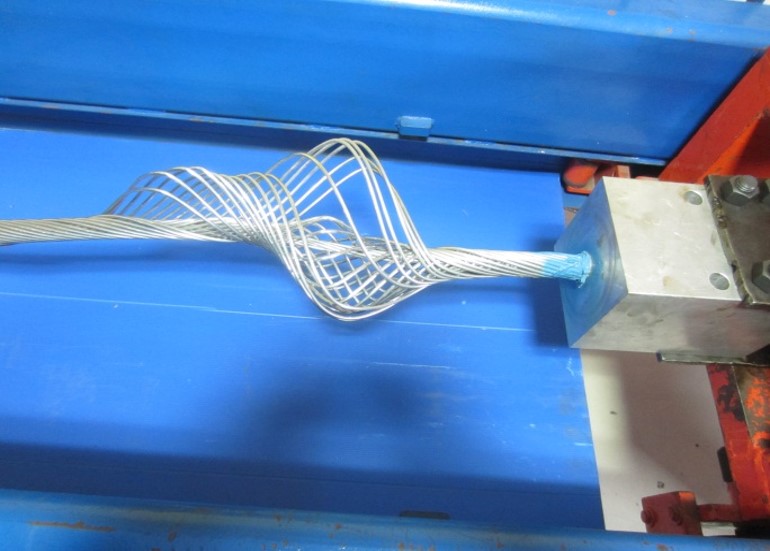

- Weld Inspections (NDT Techniques)

- Fabrication Shop Audits and On-Site Inspections

- Material Sampling for Metallurgical/Mechanical Testing

- Failure/Root Cause Analysis

- Field Inspections for Aging Transmission Infrastructure